Pnematic Control Valve ready for delivery

The Application of Thin Ball Valve

The Industrial Pneumatic Control Valve, Pneumatic Proportional Control Valve, and High Temperature Pneumatic Ball Valve from Cameron are all examples of the versatile applications of Thin Ball Valves. These compact and space-saving valves excel in a wide range of industrial settings, from general fluid control to specialized chemical and high-temperature processes. The monoblock design and carefully selected materials ensure superior durability, corrosion resistance, and reliable performance, making Thin Ball Valves a popular choice for applications that demand precision control and long service life. Whether you need precise flow regulation, on/off control, or the ability to handle extreme temperatures, the Thin Ball Valve solutions from Cameron offer the flexibility and dependability to meet your process requirements across various industries, including oil and gas, manufacturing, and power generation.

What Are The Types Of Thin Ball Valve?

- Standard Thin Ball Valve:

- Basic ball valve design with a compact, space-saving profile.

- Suitable for general fluid control applications.

- Available in a range of materials like carbon steel, stainless steel, and alloys.

- High-Performance Thin Ball Valve:

- Enhanced design and materials for more demanding applications.

- Offers improved corrosion resistance, high-temperature capabilities, and enhanced sealing.

- Commonly used in industrial processing, chemical plants, and power generation.

- Sanitary Thin Ball Valve:

- Specifically designed for hygienic and sterile applications.

- Features smooth, polished surfaces and specialized materials to prevent contamination.

- Widely used in food, beverage, pharmaceutical, and biotech industries.

- Cryogenic Thin Ball Valve:

- Engineered to operate in extremely low-temperature environments.

- Utilizes cryogenic-grade materials and seals to ensure reliable performance.

- Found in liquefied gas, LNG, and other cryogenic processing applications.

- Automated Thin Ball Valve:

- Equipped with pneumatic, electric, or hydraulic actuators for remote operation.

- Enables precise flow control and on/off functionality in automated systems.

- Commonly used in process control and instrumentation applications.

What Is Thin Ball Valve?

A Thin Ball Valve is a type of rotary control valve that features a compact, space-saving design compared to traditional ball valves. The key defining characteristic of a Thin Ball Valve is its slim profile, achieved through a monoblock construction where the valve body and end connections are integrated into a single, seamless unit. This innovative design reduces the overall footprint of the valve, making it ideal for installations with limited space or in applications where a low-profile valve is required. Thin Ball Valves are widely used across a variety of industries, including oil and gas, chemical processing, power generation, and more, providing reliable flow control and on/off functionality in a durable and efficient package.

How to Select the Right Thin Ball Valve?

When selecting the right Thin Ball Valve for your application, there are several key factors to consider:

Size and Pressure Rating: Determine the required valve size and the maximum pressure the valve will need to withstand based on your system requirements. Choose a valve with the appropriate pressure rating to ensure safe and reliable operation.

Materials of Construction: Select materials that are compatible with the process media and can withstand the operating temperatures and corrosive environments. Common materials include carbon steel, stainless steel, and specialty alloys.

End Connections: Match the valve’s end connections (e.g., flanged, threaded, or butt-weld) to the pipe configuration in your system for a secure and leak-free installation.

Valve Features: Evaluate the need for additional features such as full-bore design, anti-static properties, or fire-safe construction, depending on your specific application requirements.

By carefully considering these critical selection criteria, you can ensure that the Thin Ball Valve you choose will provide the necessary performance, durability, and safety for your process.

Features of Thin Ball Valve

Compact Design:

The defining feature of a Thin Ball Valve is its compact, space-saving design. The monoblock construction and slim profile allow for easy installation in confined spaces.

Durability:

Thin Ball Valves are engineered with high-quality materials and robust construction, providing excellent resistance to wear, corrosion, and harsh operating conditions.

Precise Flow Control:

The precise, quarter-turn operation of the ball mechanism enables accurate flow regulation and on/off control, making Thin Ball Valves suitable for a wide range of applications.

Temperature Capabilities:

Depending on the materials used, Thin Ball Valves can be designed to operate in a wide temperature range, from cryogenic to high-temperature environments.

Reduced Maintenance:

The simple, compact design of Thin Ball Valves requires minimal maintenance, reducing the overall cost of ownership and downtime.

Versatility:

Thin Ball Valves are available in a variety of end connections, materials, and specialty features to accommodate different process requirements and industry applications.

Advantages and Disadvantages of Thin Ball Valve

Advantages of Thin Ball Valve:

- Compact Size: The slim profile and monoblock design of Thin Ball Valves allow for easy installation in space-constrained environments.

- Reliable Performance: Thin Ball Valves are engineered with durable materials and robust construction, ensuring reliable operation even in harsh conditions.

- Precise Flow Control: The precise, quarter-turn operation of the ball mechanism provides accurate flow regulation and on/off control.

- Reduced Maintenance: The simple design of Thin Ball Valves requires minimal maintenance, reducing the overall cost of ownership.

- Versatility: Thin Ball Valves are available in a wide range of sizes, materials, and end connections to suit diverse application requirements.

Disadvantages of Thin Ball Valve:

- Limited Size Range: Thin Ball Valves are typically available in smaller sizes, which may not be suitable for large-scale industrial applications.

- Lower Flow Capacity: Due to their compact design, Thin Ball Valves may have a lower flow capacity compared to traditional ball valves of the same size.

- Higher Cost: The specialized manufacturing and materials required for Thin Ball Valves can make them more expensive than some other valve types.

- Limited Pressure Rating: Depending on the design and materials, Thin Ball Valves may have a lower pressure rating compared to larger ball valves.

- Potential for Leakage: The close-fitting ball and seat design of Thin Ball Valves can make them more susceptible to leakage over time, especially in high-cycle applications.

The Specifications of Thin Ball Valve

| Specification | Details |

|---|---|

| Type | Standard Thin Ball Valve |

| Ball Material | 316 Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | 316 Stainless Steel |

| Safe for Use With | Corrosive fluids, water, oil, air, and gas |

| Handle Type | Lever |

| Handle Material | 304 Stainless Steel |

| Maximum Working Pressure (psi) | 1000 psi |

| Maximum Working Pressure (bar) | 69 bar |

| Operating Pressure | 0-1000 psi (0-69 bar) |

The Installation Steps for Thin Ball Valve

- Prepare the Pipe System: Ensure the pipe system is clean, free of debris, and the correct pipe size for the valve.

- Select the Appropriate Valve: Verify that the Thin Ball Valve’s size, pressure rating, and materials of construction are suitable for the application.

- Mark the Pipe: Measure and mark the pipe where the valve will be installed, allowing for sufficient clearance around the valve.

- Cut the Pipe: Use the appropriate tool to make a clean, square cut on the pipe at the marked location.

- Deburr and Clean the Pipe Ends: Remove any burrs or sharp edges from the pipe ends to prevent damage to the valve seals.

- Apply Sealant or Thread Tape: For threaded connections, apply a suitable sealant or PTFE thread tape to the valve’s threads.

- Install the Valve: Carefully insert the Thin Ball Valve into the pipe, ensuring the correct orientation and tightening the connections securely.

- Perform Leak Testing: Once the valve is installed, check for any leaks at the connections using an appropriate leak detection method.

- Operate the Valve: Slowly open and close the valve to ensure smooth operation and proper flow control.

- Document the Installation: Record the valve’s location, size, and other relevant information for future reference and maintenance purposes.

The Operation Theory of Thin Ball Valve

Operation Theory of Thin Ball Valve:

- Ball Mechanism: The core of a Thin Ball Valve is the spherical ball that rotates 90 degrees to open and close the valve. This quarter-turn operation provides precise flow control.

- Sealing Surfaces: The ball sits against a soft, flexible seat material, such as PTFE or reinforced PTFE, creating a tight seal when the valve is closed.

- Pressurized Flow: When the valve is open, the process fluid or gas flows around the ball, with the thin profile of the valve minimizing pressure drop and turbulence.

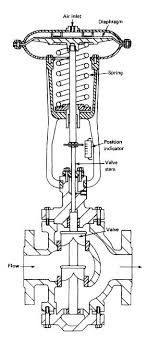

Precision Pneumatic Control Valve:

Pneumatic control valves, often used in conjunction with Thin Ball Valves, utilize compressed air to precisely actuate the valve. This allows for accurate, fast, and reliable flow control in response to process changes or control system commands.

Chemical Industry Pneumatic Actuator:

In the chemical industry, Thin Ball Valves are commonly paired with pneumatic actuators that are designed to withstand harsh, corrosive environments. These actuators use compressed air to open and close the valve, providing precise control and reliable operation in demanding chemical processing applications.

The combination of the Thin Ball Valve’s compact design and the precision control of pneumatic actuation makes this valve configuration well-suited for a wide range of industrial and chemical process applications.