Triple Offset Butterfly Valve

The Application of Triple Offset Butterfly Valve

The Triple Offset Butterfly Valve is a state-of-the-art solution in fluid control, manufactured through a rigorous industrial valve manufacturing process. Unlike traditional hvac valve types, it features a unique design that minimizes friction and wear, similar to the Intec Duoball Valve or KGC-BD knife gate valve. With brands like Cameron renowned for quality brass ball valves, and suppliers like SKG Pneumatics Inc offering precision butterfly valve seats, the Triple Offset Butterfly Valve ensures reliability and durability. Its innovative design makes it ideal for demanding applications where tight shut-off and zero leakage are critical, such as in oil and gas, petrochemical, and power generation industries. This valve’s exceptional performance and longevity make it a preferred choice among industrial valve manufacturers.

Features of Triple Offset Butterfly Valve

- Our triple offset butterfly valve features a replaceable valve seat, allowing easy on-site replacement without disrupting pipeline operation.

- Users can select from various materials for the valve body and sealing surfaces to meet specific working conditions.

- The valve support complies with ISO 5211 standards, enabling convenient interchangeability of actuators.

- A combined packing sealing system ensures minimal leakage, with the option to choose a dynamic load sealing structure for longer packing life.

The Parameter of Triple Offset Butterfly Valve

- Pressure Rating: Triple Offset Butterfly Valves typically have a high-pressure rating, ranging from Class 150 to Class 2500.

- Temperature Range: Capable of operating within a wide temperature range, from cryogenic temperatures to high temperatures up to 1000°F (537°C).

- Size Range: Available in various sizes, from as small as 2 inches to as large as 72 inches or more.

- Design Standards: Manufactured in compliance with industry standards such as API 609, ASME B16.34, and ISO 14313.

- Material: Constructed from high-quality materials such as stainless steel, carbon steel, or exotic alloys to withstand corrosive environments.

- Sealing System: Equipped with a triple offset design for tight shut-off and low leakage rates, typically ≤20 ppm.

- Actuation: Compatible with various actuation methods including manual, electric, pneumatic, or hydraulic actuators.

- End Connections: Available with a variety of end connection options including wafer, lug, or flanged ends for easy installation in different piping systems.

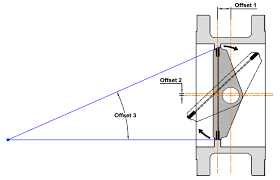

The Operation Theory of Triple Offset Butterfly Valve

The operation theory of Triple Offset Butterfly Valve involves a unique design that minimizes friction and wear, similar to the Intec Duoball. Unlike traditional globe valve vs ball valve, it offers precise control and tight shut-off. Ideal for various applications, including those in cooling tower valves company, it ensures reliable performance even in extreme conditions. Compared to ball valve vs globe valve, it provides superior sealing and lower leakage rates, typically ≤20 ppm. Designed in compliance with industry standards such as API and rating, it operates efficiently across a wide temperature range.

The Parameters Table of Triple Offset Butterfly Valve

| Parameter | Description |

|---|---|

| Material | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Pressure Rating | Class 150 to Class 2500 |

| Temperature Range | -450°F to 1000°F (-268°C to 537°C) |

| Size Range | 2 inches to 72 inches or more |

| Design Standards | API 609, ASME B16.34, ISO 14313 |

| Sealing System | Triple Offset Design for Tight Shut-off, Low Leakage |

| Actuation | Manual, Electric, Pneumatic, Hydraulic |

| End Connections | Wafer, Lug, Flanged |

Relevant Information about Triple Offset Butterfly Valve

- Rotor: The rotating disc that controls the flow of fluid through the valve.

- Stator: The stationary part of the valve that supports the rotor and maintains alignment.

- Universal Joint: Not typically present in butterfly valves.

- Shaft Seal: Prevents leakage along the valve shaft, ensuring a tight seal.

- Driving System: Manual operation or actuation using electric, pneumatic, or hydraulic systems to control the position of the rotor.